Industrial Stairs

Industrial Stairs have a climbing angle between 30° and 45° which means the climber can carry such items as toolboxes, equipment, supplies, etc., while accessing mezzanines, catwalks or roof hatches and still comply with OSHA standards. The much lighter weight of these units as compared to traditional steel ones make them much easier to install, and the aluminum construction

also makes them virtually maintenance-free. These stairways are built per job conditions and shipped to the job site ready to install.

Some important characteristics of these ladders are:

- All components shall be aluminum alloy 6005-T5

- Fully welded construction throughout

- Stringers are 8″ x 2.29″ x 1/4″ aluminum channel

- Treads are aluminum bar grating (standard) both welded and bolted to stringer to withstand a minimum 1000 loading per tread (depth determined by rise and run)

- Stair Rail Systems are 2-line, 1-1/4′′ schedule 40 pipe (1.66′′ OD),

with integral handrail - Mill finish aluminum

- Available in pitches from 30 degrees to 45 degrees

Available as options:

- Widths up to 60”

- Other finishes: powder coat

- Anti-slip plate treads (formed tread with grip tape)

- Special applications: “Crossover” or “bridge” stairs, landing platforms, catwalks

014 Page Color Brochure

02Industrial Stairway Product Specification

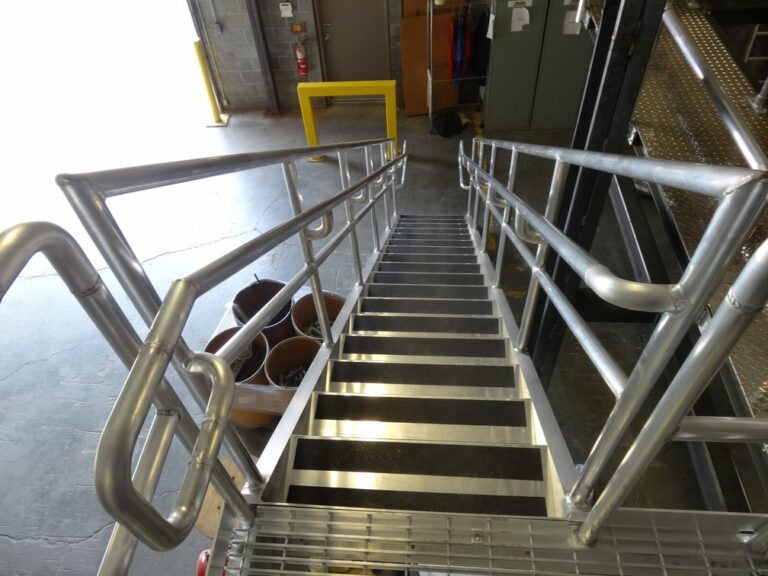

03Industrial Stairway with bar grating treads

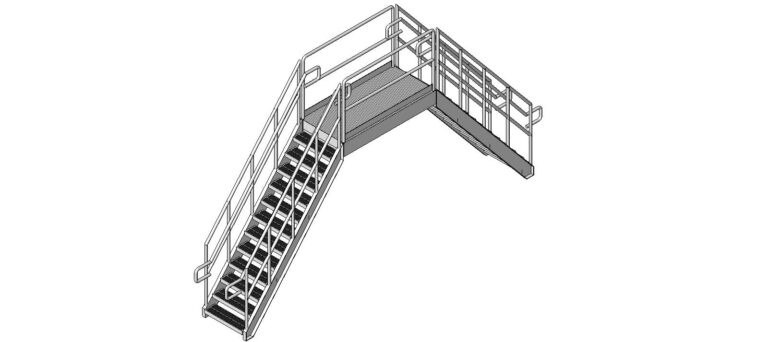

04Industrial Stairway with platform at top

05Industrial Stairway to roof hatch

06Industrial Crossover Stairway